News

Tesla’s simple Model 3 drivetrain design is key to its mass market future

One can argue that the simplicity in design of the Tesla Model 3 drivetrain and subframe assembly is a key to Tesla’s future. Used in both the Model 3 and the Tesla Semi, while also serving as a platform for Tesla’s upcoming Model Y, the powerful and efficient drivetrains are designed with versatility in mind, as recently highlighted by auto enthusiast Ingineerix on YouTube.

In the short video clip, a Tesla drive unit retrieved from a totaled Model 3 aims to highlight the straightforward design of the all-electric drivetrain that lends itself to ease of manufacturing. Aside from a housing for the inverter and permanent magnet switch reluctance motor, only a handful of electrical connectors could be seen, including a high-voltage connector that leads to Model 3’s battery pack, and a data connector. The entire subframe is attached to the Model 3’s chassis by four bolts, which, when removed, allows the whole assembly to be detached cleanly from the vehicle.

The Long Range RWD Model 3’s drive unit is rated at 211 kW, powerful enough to propel the electric car from a dead stop to 60 mph in 5.1 seconds. The simplicity of the drivetrain’s design is further exemplified by the company’s usage of four Model 3 electric motors in Tesla’s tire-shredding electric Semi truck.

When Elon Musk unveiled the Model 3, he made it a point to emphasize that the vehicle is designed to be as simple as possible. Everything, from its chassis to its electric motor, was built with efficiency and simplicity in mind.

In an era of DIYers and their knack for resurrected Frankenstein projects, Tesla Model 3’s drive unit could very well prove to be popular with hobbyists and aftermarket companies looking to capitalize on electric vehicle conversions. This will especially hold true as electric vehicles start to command a significant market share and manufacturing of electric drivetrains, along with access to salvaged vehicles, become more prevalent.

The Model 3 is one of the final phases of Elon Musk’s first Master Plan, which he penned back in 2006. During that time, Musk envisioned the Model 3 to be a vehicle that brings EVs mainstream. Almost twelve years down the road, with Tesla seemingly hitting its pace to the deliver the Model 3 en masse to reservation holders, it appears that the electric car is doing just that.

Tesla’s drive units are quite durable, with a Tesla Model S recently passing the 400,000-mile mark on the road. Thus, it seems safe to assume that the Model 3’s drive unit would be just as durable, if not even better built, than Tesla’s first-generation electric motor. Tesla is aiming to produce around 500,000 Model 3 in a year. That’s half a million electric cars with drivetrains that could easily be detached and used for optimal EV conversions, even after the Model 3 is retired. With the Model 3, Tesla might have really created a car that can usher in a new era of automobiles.

Watch a quick walkthrough of a detached Model 3 drive unit in the video below.

Elon Musk

Elon Musk confirms Grok 4 launch on July 9 with livestream event

The rollout will be accompanied by a livestream at 8 p.m. Pacific Time.

Elon Musk has officially confirmed that Grok 4, the latest version of xAI’s large language model, will launch on July 9. The rollout will be accompanied by a livestream at 8 p.m. Pacific Time, hosted on xAI’s official account on X.

xAI goes straight to Grok 4

Back in May, leaks indicated that xAI was getting ready to ship Grok 3.5. Considering Musk’s recent comments, however, it appears that the artificial intelligence startup would be focusing on the large language model’s fourth iteration instead. As noted in a Financial Express report, users on X have sighted references to Grok 4 in the lead up to the update’s launch, such as “grok-4-prod-mimic” and “Grok 4 Code.”

Musk’s Grok 4 announcement comes as AI competition intensifies between major players including OpenAI, Google, and xAI. With Musk’s Colossus supercomputer fully operational in Memphis, xAI appears to be accelerating its AI product roadmap.

Musk pushes Grok toward political neutrality

Grok 4’s launch also follows a recent controversy involving political bias, as noted in a CNN report. Last week, Grok responded to a user on X stating that political violence in the U.S. since 2016 had come more from the political right than the left. The chatbot noted in a later reply that its answer was based on information from sources like Reuters, the Journal of Democracy, and University of Maryland studies.

Musk stated that Grok’s response was a “major fail.” “Major fail, as this is objectively false. Grok is parroting legacy media. Working on it,” he wrote in a post on X. By the end of June, Musk noted that he was “grinding all night with the xAI team” and that they were making “good progress.” He also stated that the model “Will be called Grok 4. Release just after July 4th. Needs one more big run for a specialized coding model.”

News

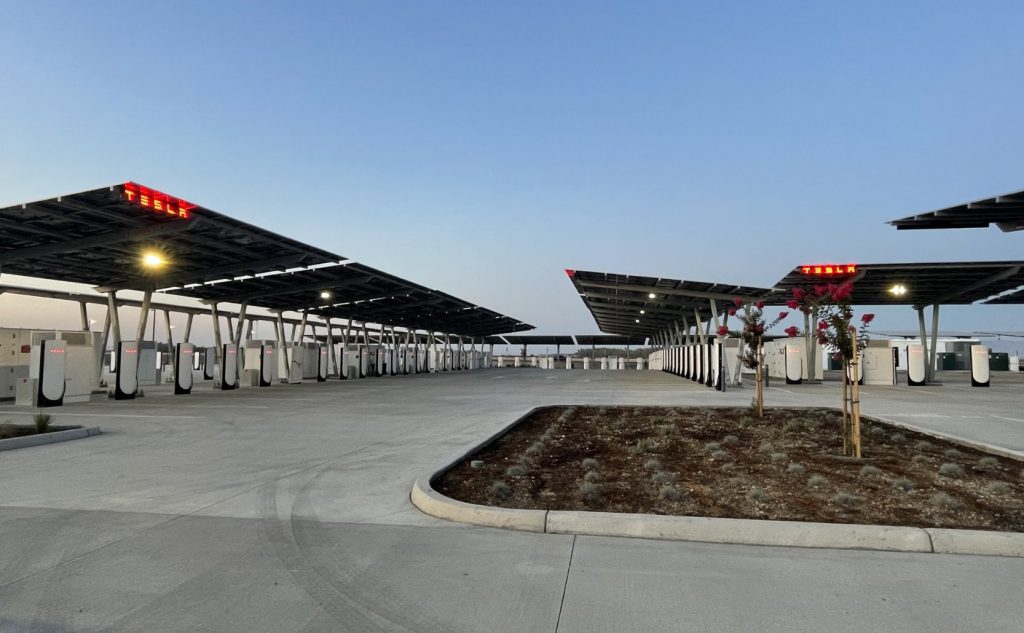

Tesla opens massive solar Supercharger station in California

The Supercharger opened to customers ahead of Fourth of July weekend, while Tesla continues phase two of construction on the site.

Tesla has officially launched the first several Supercharging posts at a massive station in California, notably including solar canopies and grid-scale batteries to offer completely renewable charging.

Last week, Tesla announced on X that it opened the first 84 Supercharger stalls of a planned 168-stall station in Lost Hills, California. Additionally, the massive Supercharger project features 11MW of solar canopies and 10 Megapack batteries for off-grid charging powered entirely by solar energy.

Tesla completed the first phase of the project just days ahead of the busy Fourth of July holiday weekend, adding that initial construction took just eight months. In addition to the remaining charging stalls, Tesla says it’s building a set of lounge areas, renderings of which can be seen below alongside current photos of the site.

Notably, the site also includes V4 charging posts for the company’s latest available charging speeds, and it’s located near the busy junction between I-5 and Highway 46 in Kern County.

“Thank you [Kern County] and [PG&E] for collaboration and approvals,” Tesla wrote in a follow-up post.

Credit: Tesla Charging | X

Credit: Tesla Charging | X

Credit: Tesla Charging | X

Credit: Tesla Charging | X

Tesla Supercharger Maps for North America, Europe, and Asia pic.twitter.com/0U5r0XRPyo

— TESLARATI (@Teslarati) July 2, 2025

READ MORE ON TESLA SUPERCHARGERS: Tesla launches ultra-fast V4 Superchargers in China for the first time

Testing at the LA Diner, plus Musk update on potential Tesla solar Gigafactory

The huge Tesla Supercharger station completed phase one of construction fairly quickly, especially given how long Tesla has been working on its unique Los Angeles diner, drive-in, and Supercharger location. Still, the company was seen performing some testing at the nearly-completed charging station earlier this month, and will reportedly be holding a job fair.

Elon Musk also responded on Monday morning to a post on X, suggesting that Tesla is “thinking about” building a U.S.-based solar Gigafactory in order to help support increased power needs with AI growth, and to bolster domestic solar production.

Tesla is building a new UFO-inspired Supercharger in the heart of Alien country

News

Tesla driver walks away from major accident with minor injuries

The driver sustained only minor injuries, and the exact cause of the crash remains under investigation.

The driver of a Tesla Model Y survived and walked away from a harrowing accident on Monday in California, only sustaining minor injuries despite the vehicle being impaled by a guardrail.

On Monday morning around 4:34 a.m., the Los Banos division of the California Highway Patrol (CHP) responded to the accident on I-5 near Panoche Road, involving a 23-year-old in a Tesla Model Y. According to a post on social media, the driver veered off the road for unknown reasons in the northbound lane, before crashing directly into the guardrail and impaling the vehicle.

You can read the full message and photos from Los Banos CHP below, as were shared in a Facebook post on Monday afternoon.

This morning a Tesla model y was traveling in the #1 northbound lane of I-5 north of Panoche Rd. For unknown reasons driver allowed V-1 to veer off the roadway, travel through a dirt center divide, and crashed into the fixed metal guardrail. Lucky for the driver he only sustained minor injuries and was able to walk away. Driving a vehicle requires 100% attention to the road. Avoid distractions and focus on driving.

Credit: CHP Los Banos (via Facebook)

Credit: CHP Los Banos (via Facebook)

Credit: CHP Los Banos (via Facebook)

In a statement to SFGate, CHP officer Myles Anderson said that the driver only sustained minor injuries, while no arrests are made and drugs and alcohol are not suspected to have been involved. The report also notes that Tesla’s “cruise control and lane assistance features” were activated, according to Anderson. However, it’s not entirely clear if this is referring to Supervised Full Self-Driving (FSD), or to the cruise control and lane assist features baked into Autopilot.

At the time of writing, CHP has not yet responded to Teslarati’s request for clarification and additional details on the matter.

Tesla Crash Safety Ratings across its lineup: pic.twitter.com/ny30R7ceji

— TESLARATI (@Teslarati) July 1, 2025

READ MORE ON TESLA SAFETY: Tesla rolls out crucial new safety feature aimed at saving children

The news comes after Tesla has touted its vehicles as incredibly safe for many years. In December, for example, the company highlighted receiving top safety scores from regulators on four different continents throughout the world, including from the National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute of Highway Safety (IIHS) in the U.S.

Tesla has also listed the goal of making its vehicles the safest on the road throughout the years, both in the overall design of its vehicles and in its Autopilot and Full Self-Driving (FSD) programs.

Tesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News2 weeks ago

News2 weeks agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

News2 weeks ago

News2 weeks agoWatch the first true Tesla Robotaxi intervention by safety monitor

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

News2 weeks ago

News2 weeks agoTesla Robotaxi rollout proves that Elon Musk still delivers, even if it’s late

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI welcomes Memphis pollution results, environmental groups push back

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk commends Tesla team on successful Robotaxi launch

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk confirms Tesla Optimus V3 already uses Grok voice AI