News

Blue Origin teases first New Glenn rocket prototype at Blue Moon lander event

In May 2019, Blue Origin unveiled plans to build and launch “Blue Moon” lunar landers. Five months later, founder Jeff Bezos has announced a proposal for NASA’s Artemis Moon lander program that would augment Blue Moon with hardware from aerospace stalwarts Lockheed Martin, Northrop Grumman, and Draper to land astronauts on the Moon in the 2020s.

On top of that, Bezos also revealed the first unequivocal confirmation that Blue Origin has begun building full-scale prototype hardware for its ambitious New Glenn orbital launch vehicle – in this case, half of a massive carbon fiber payload fairing.

In a press release posted to the company’s website, Blue Origin’s Chief Executive Officer, Bob Smith, stated that “national challenges call for a national response. We are humbled and inspired to lead this deeply committed team that will land NASA astronauts on the Moon.” The national team will be managed with Blue Origin as the principal contractor and “[combine] our partners’ heritage with our advance work on the Blue Moon lunar lander and its BE-7 engine.”

Solving the lunar landing equation

Each company was selected based on a demonstrated area of expertise that solves a very specific piece of the equation that is landing astronauts on the moon. Blue Origin will serve as the primary contractor leading mission engineering and assurance, as well as providing the lunar Descent Element, Blue Moon. Lockheed Martin will provide the reusable Ascent Element vehicle and lead the operations and flight training of the crew, while Northrop Grumman provides the Transfer Element vehicle to deliver Blue Moon to the lunar surface.

Draper’s contribution is integral to mission success. It will provide a navigation system “designed to give crewed missions precise location and navigation data needed for safe and accurate lunar and planetary landings” as outlined in a NASA Space Technology Mission Directorate statement earlier this month. The Draper navigation system is expected to debut during a launch of Blue Origin’s suborbital rocket, New Shepard as proof of concept by year’s end.

Debuting super-heavy rocket hardware

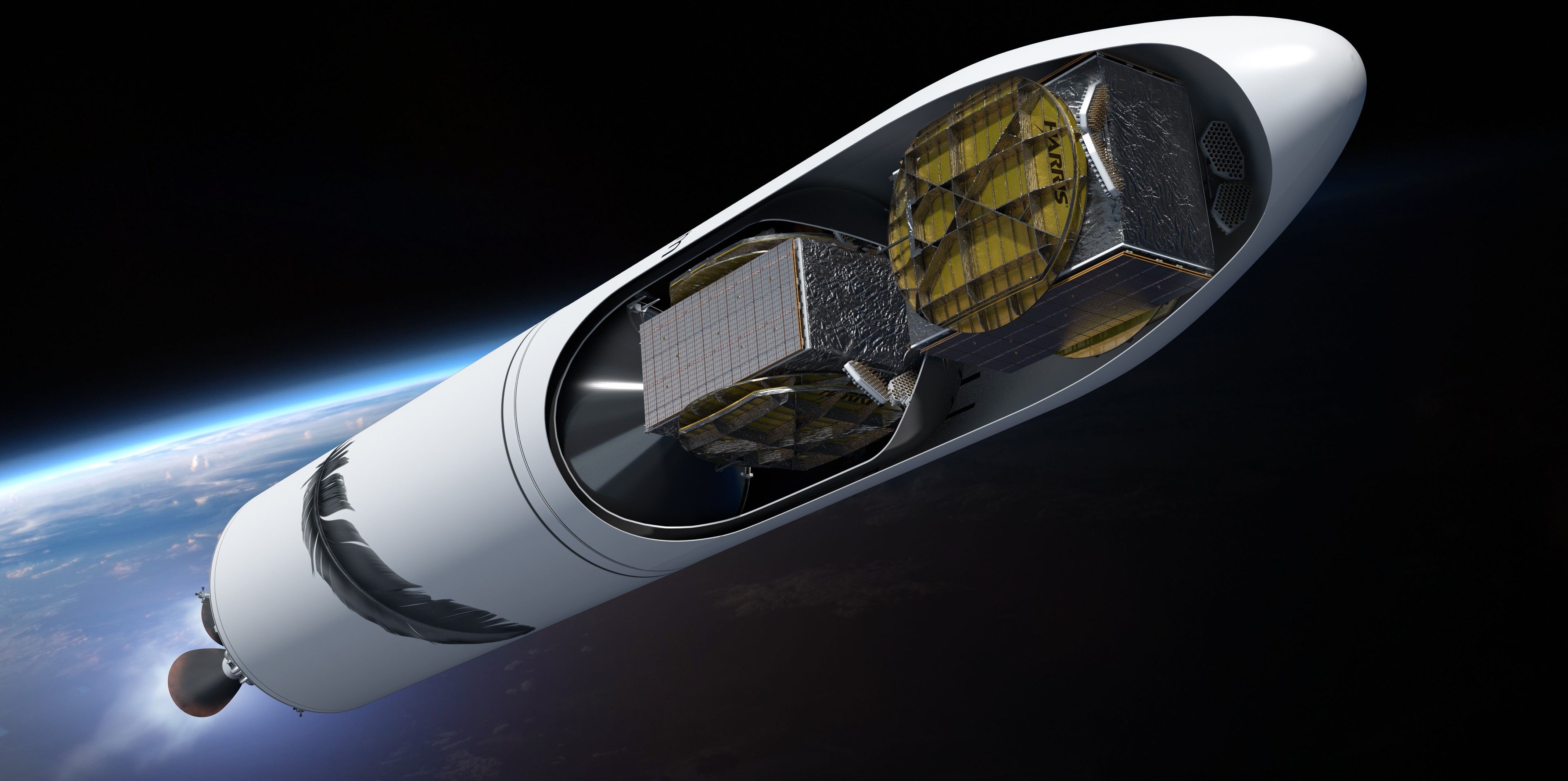

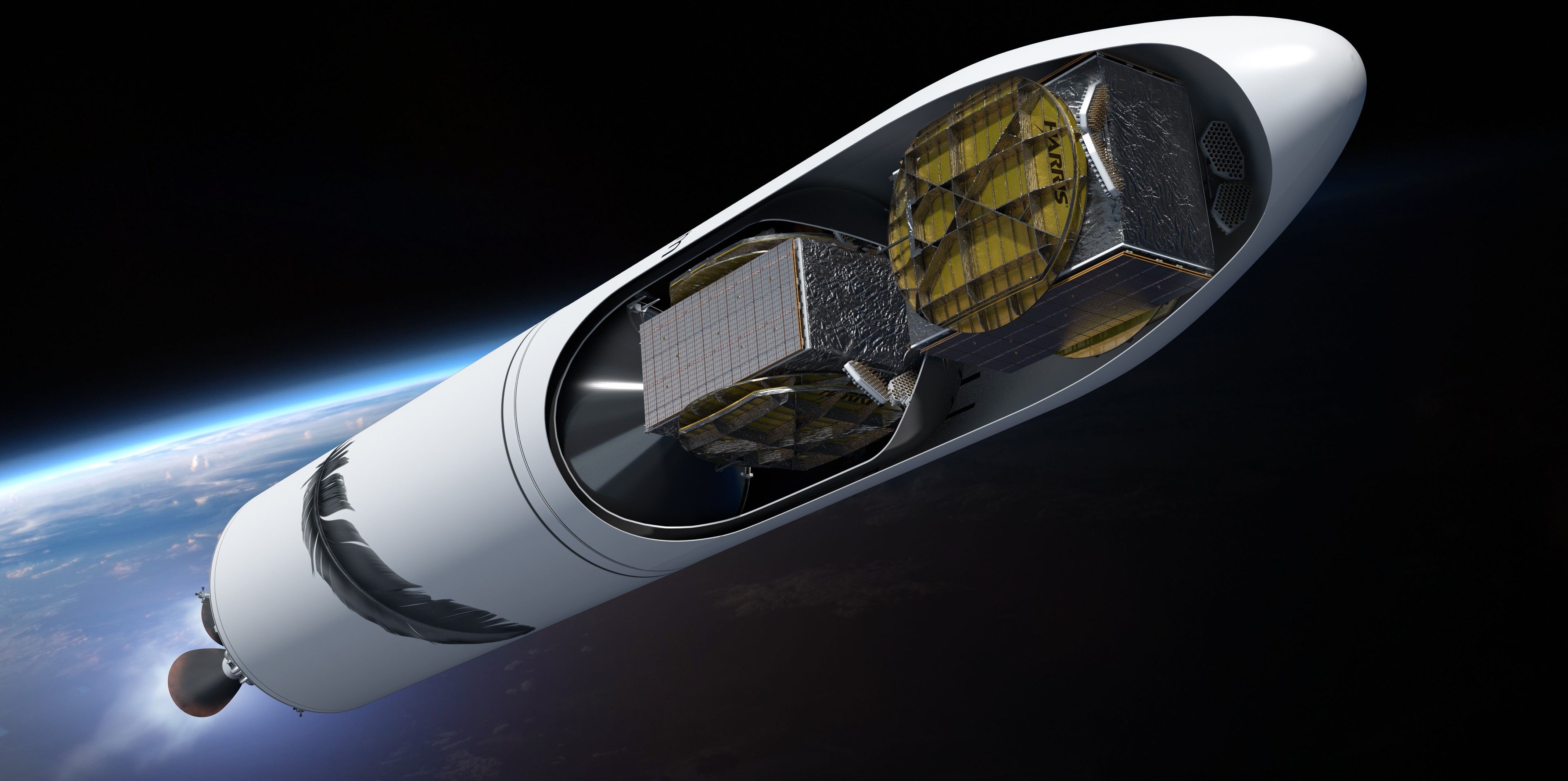

During his IAC presentation, Bezos revealed a video of what is almost certainly the first full-scale prototype hardware of Blue Origin’s reusable New Glenn rocket. In the clip, a massive carbon-composite payload fairing half is moved inside an even larger curing oven located on Blue Origin’s Cape Canaveral, FL campus, offering an incredibly rare glimpse inside the company’s purported New Glenn factory.

New Glenn’s payload fairing will measure 7m (23 ft) wide and roughly 22m (72 ft) tall, dwarfing the 5ish-meter options currently used by SpaceX and ULA. As of now, New Glenn’s payload fairing will be the largest expendable fairing on Earth when it debuts in 2021 or 2022.

Aside from a Blue Moon lander mockup, Blue Origin also brought an entire BE-4 engine to IAC 2019. Seven BE-4s will power New Glenn’s reusable first stage and the United Launch Alliance (ULA) has also selected BE-4 to power its Vulcan booster. Capable of producing roughly 550,000 lbf (2400 kN) of thrust, Blue Origin is slowly but surely qualifying BE-4 for flight and recently began its first full-thrust static fires at the company’s Van Horn, Texas test facilities.

While Bezos’s presentation provided the briefest of views inside Blue Origin’s rocket factory, Space Coast local Julia Bergeron posted a photo on Twitter showing an impressive fleet of cranes hard at work building Blue Origin’s LC-36 New Glenn launch pad in Cape Canaveral, Florida.

Blue Origin is notoriously hesitant to share much of anything about its next-generation New Glenn rocket, so it’s a pleasant surprise to receive even the briefest of glimpses behind the scenes. Combined with Blue’s undeniable rocket propulsion expertise and shrewdly political (albeit unsavory) approach to industry collaboration, the company is clearly here to stay and is certainly doing everything it can to give NASA an offer it simply can’t refuse.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

These Tesla, X, and xAI engineers were just poached by OpenAI

The news is the latest in an ongoing feud between Elon Musk and the Sam Altman-run firm OpenAI.

OpenAI, the xAI competitor for which Elon Musk previously served as a boardmember and helped to co-found, has reportedly poached high-level engineers from Tesla, along with others from xAI, X, and still others.

On Tuesday, Wired reported that OpenAI hired four high-level engineers from Tesla, xAI, and X, as seen in an internal Slack message sent by co-founder Greg Brockman. The engineers include Tesla Vice President of Software Engineering David Lau, X and xAI’s head of infrastructure engineering Uday Ruddarraju, and fellow xAI infrastructure engineer Mike Dalton. The hiring spree also included Angela Fan, an AI researcher from Meta.

“We’re excited to welcome these new members to our scaling team,” said Hannah Wong, an OpenAI spokesperson. “Our approach is to continue building and bringing together world-class infrastructure, research, and product teams to accelerate our mission and deliver the benefits of AI to hundreds of millions of people.”

Lau has been in his position as Tesla’s VP of Software Engineering since 2017, after previously working for the company’s firmware, platforms, and system integration divisions.

“It has become incredibly clear to me that accelerating progress towards safe, well-aligned artificial general intelligence is the most rewarding mission I could imagine for the next chapter of my career,” Lau said in a statement to Wired.

🚨Optimistic projections point to xAI possibly attaining profitability by 2027, according to Bloomberg's sources.

If accurate, this would be quite a feat for xAI. OpenAI, its biggest rival, is still looking at 2029 as the year it could become cash flow positive.💰 https://t.co/pE5Z9daez8

— TESLARATI (@Teslarati) June 18, 2025

READ MORE ON OPENAI: Elon Musk’s OpenAI lawsuit clears hurdle as trial looms

At xAI, Ruddarraju and Dalton both played a large role in developing the Colossus supercomputer, which is comprised of over 200,000 GPUs. One of the major ongoing projects at OpenAI is the company’s Stargate program,

“Infrastructure is where research meets reality, and OpenAI has already demonstrated this successfully,” Ruddarraju told Wired in another statement. “Stargate, in particular, is an infrastructure moonshot that perfectly matches the ambitious, systems-level challenges I love taking on.”

Elon Musk is currently in the process of suing OpenAI for shifting toward a for-profit model, as well as for accepting an investment of billions of dollars from Microsoft. OpenAI retaliated with a counterlawsuit, in which it alleges that Musk is interfering with the company’s business and engaging in unfair competition practices.

Elon Musk confirms Grok 4 launch on July 9 with livestream event

News

SpaceX share sale expected to back $400 billion valuation

The new SpaceX valuation would represent yet another record-high as far as privately-held companies in the U.S. go.

A new report this week suggests that Elon Musk-led rocket company SpaceX is considering an insider share sale that would value the company at $400 billion.

SpaceX is set to launch a primary fundraising round and sell a small number of new shares to investors, according to the report from Bloomberg, which cited people familiar with the matter who asked to remain anonymous due to the information not yet being public. Additionally, the company would sell shares from employees and early investors in a follow-up round, while the primary round would determine the price for the secondary round.

The valuation would represent the largest in history from a privately-owned company in the U.S., surpassing SpaceX’s previous record of $350 billion after a share buyback in December. Rivaling company valuations include ByteDance, the parent company of TikTok, as well as OpenAI.

Bloomberg went on to say that a SpaceX representative didn’t respond to a request for comment at the time of publishing. The publication also notes that the details of such a deal could still change, especially depending on interest from the insider sellers and share buyers.

Axiom’s Ax-4 astronauts arriving to the ISS! https://t.co/WQtTODaYfj

— TESLARATI (@Teslarati) June 26, 2025

READ MORE ON SPACEX: SpaceX to decommission Dragon spacecraft in response to Pres. Trump war of words with Elon Musk

SpaceX’s valuation comes from a few different key factors, especially including the continued expansion of the company’s Starlink satellite internet company. According to the report, Starlink accounts for over half of the company’s yearly revenue. Meanwhile, the company produced its 10 millionth Starlink kit last month.

The company also continues to develop its Starship reusable rocket program, despite the company experiencing an explosion of the rocket on the test stand in Texas last month.

The company has also launched payloads for a number of companies and government contracts. In recent weeks, SpaceX launched Axiom’s Ax-4 mission, sending four astronauts to the International Space Station (ISS) for a 14-day stay to work on around 60 scientific experiments. The mission was launched using the SpaceX Falcon 9 rocket and a new Crew Dragon capsule, while the research is expected to span a range of fields including biology, material and physical sciences, and demonstrations of specialized technology.

News

Tesla Giga Texas continues to pile up with Cybercab castings

Tesla sure is gathering a lot of Cybercab components around the Giga Texas complex.

Tesla may be extremely tight-lipped about the new affordable models that it was expected to start producing in the first half of the year, but the company sure is gathering a lot of Cybercab castings around the Giga Texas complex. This is, at least, as per recent images taken of the facility.

Cybercab castings galore

As per longtime drone operator Joe Tegtmeyer, who has been chronicling the developments around the Giga Texas complex for several years now, the electric vehicle maker seems to be gathering hundreds of Cybercab castings around the factory.

Based on observations from industry watchers, the drone operator appears to have captured images of about 180 front and 180 rear Cybercab castings in his recent photos.

Considering the number of castings that were spotted around Giga Texas, it would appear that Tesla may indeed be preparing for the vehicle’s start of trial production sometime later this year. Interestingly enough, large numbers of Cybercab castings have been spotted around the Giga Texas complex in the past few months.

Cybercab production

The Cybercab is expected to be Tesla’s first vehicle that will adopt the company’s “unboxed” process. As per Tesla’s previous update letters, volume production of the Cybercab should start in 2026. So far, prototypes of the Cybercab have been spotted testing around Giga Texas, and expectations are high that the vehicle’s initial trial production should start this year.

With the start of Tesla’s dedicated Robotaxi service around Austin, it might only be a matter of time before the Cybercab starts being tested on public roads as well. When this happens, it would be very difficult to deny the fact that Tesla really does have a safe, working autonomous driving system, and it has the perfect vehicle for it, too.

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News2 weeks ago

News2 weeks agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

Elon Musk1 day ago

Elon Musk1 day agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News2 weeks ago

News2 weeks agoWatch the first true Tesla Robotaxi intervention by safety monitor

-

News5 days ago

News5 days agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk confirms Tesla Optimus V3 already uses Grok voice AI

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI welcomes Memphis pollution results, environmental groups push back