News

Elon Musk’s updates to Tesla Battery Day show we have no idea what will happen

Tesla’s Battery Day is less than a month away, and there is no shortage of speculation for what might be unveiled at the event. Numerous attempts to uncover subliminal messages within Tesla’s announcements and other related topics of discussion have been shot down by CEO Elon Musk, relatively confirming the fact that, as a community, we have no idea what will go down on September 22nd.

Battery Day is arguably Tesla’s most anticipated event because of the significance it holds for the company’s future development. Not only could Tesla revolutionize the way electric cars operate, but it could reveal the company’s plans to reach price parity with gas vehicles. What goes down on September 22nd is going to be huge, and the EV community as a whole will be watching.

Initially, several members of the EV community had uncovered the fact that Amprius Technologies Headquarters is located right across the street from Tesla’s Kato Road Facility in Fremont, California. In fact, CleanTechnica had even revealed that there could be a link between Tesla and Amprius in an article from August 26th.

There was plenty of evidence that Tesla could be using Amprius Technologies silicon nanowire tech for its new cell developments.

However, Musk immediately shot down any speculation of the two companies being linked.

But actually nothing. Was surprised to hear they’re across the road. Adding silicon to carbon anode makes sense. We already do. Question is just what ratio of silicon to carbon & what shape? Silicon expands like crazy during discharge & comes apart, so cycle life is usually bad.

— Elon Musk (@elonmusk) August 27, 2020

To add fuel to the fire, Tesla also released a cryptic background for its Battery Day and Shareholder Meeting Livestream page, which left many people interested in what the design could mean.

For example, Electrek indicated that doing a simple reverse lookup of the image on Google revealed that it also had a similar design to silicon nanowires, which also would relate Tesla to Amprius once again.

While the EV community has been baffled by what the design is for the Battery Day and Shareholder, Musk finally provided an update on the image.

“We were too obtuse for our own good, although I think it works aesthetically,” Musk said in a Tweet that was in response to an inquiry from @WholeMarsBlog. “Those are folded-over current collectors at the top/bottom of the cell, which are important, but I don’t want to jump the gun on Sept 22,” he added.

Current collectors are crucial for enhancing the electrochemical performance of a lithium-ion battery cell. Usually made of aluminum or copper foils, the collectors are attached to binders that do not reach optimal capacity. However, a paper from Yuan Yue and Hong Liang states that when these collectors are damaged from discharge induced detachment of the cast layer, structural integrity compromisation occurs. This damage is usually the product of extended cycles of charging and can be detrimental to the lifespan of a cell.

Whether that has anything to do with what Tesla will unveil at its Battery Day event is unknown. However, speculating of what could occur is a good thing, because it allows members of the community to work together to try and decipher what could happen.

In the meantime, all attempts to unravel Tesla’s plan have been foiled by Musk, indicating that nobody really has any idea what the company has in store for the future of electric vehicles and energy storage systems.

News

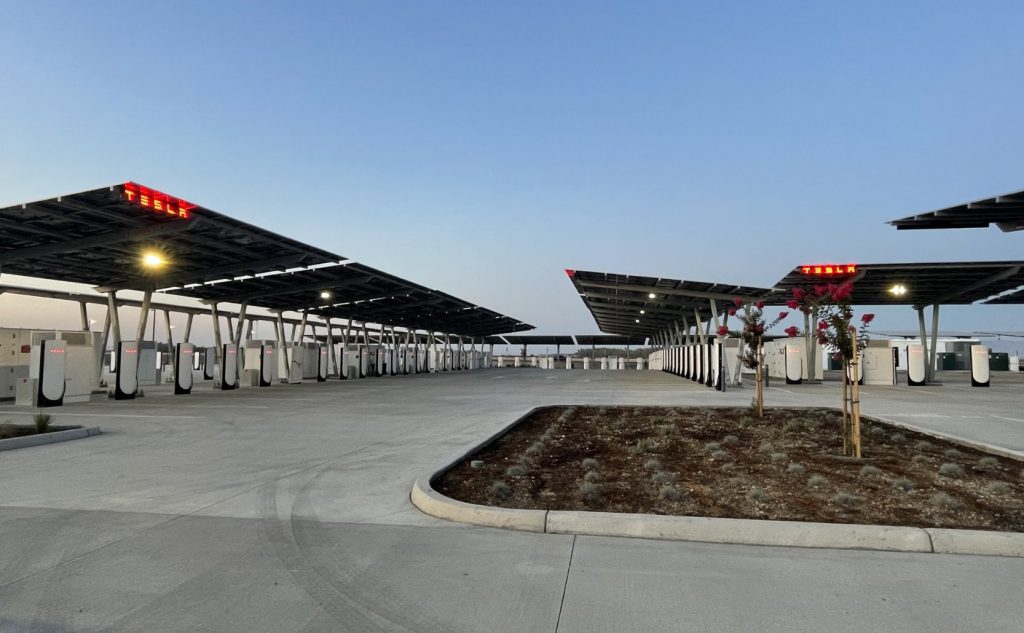

Tesla opens massive solar Supercharger station in California

The Supercharger opened to customers ahead of Fourth of July weekend, while Tesla continues phase two of construction on the site.

Tesla has officially launched the first several Supercharging posts at a massive station in California, notably including solar canopies and grid-scale batteries to offer completely renewable charging.

Last week, Tesla announced on X that it opened the first 84 Supercharger stalls of a planned 168-stall station in Lost Hills, California. Additionally, the massive Supercharger project features 11MW of solar canopies and 10 Megapack batteries for off-grid charging powered entirely by solar energy.

Tesla completed the first phase of the project just days ahead of the busy Fourth of July holiday weekend, adding that initial construction took just eight months. In addition to the remaining charging stalls, Tesla says it’s building a set of lounge areas, renderings of which can be seen below alongside current photos of the site.

Notably, the site also includes V4 charging posts for the company’s latest available charging speeds, and it’s located near the busy junction between I-5 and Highway 46 in Kern County.

“Thank you [Kern County] and [PG&E] for collaboration and approvals,” Tesla wrote in a follow-up post.

Credit: Tesla Charging | X

Credit: Tesla Charging | X

Credit: Tesla Charging | X

Credit: Tesla Charging | X

Tesla Supercharger Maps for North America, Europe, and Asia pic.twitter.com/0U5r0XRPyo

— TESLARATI (@Teslarati) July 2, 2025

READ MORE ON TESLA SUPERCHARGERS: Tesla launches ultra-fast V4 Superchargers in China for the first time

Testing at the LA Diner, plus Musk update on potential Tesla solar Gigafactory

The huge Tesla Supercharger station completed phase one of construction fairly quickly, especially given how long Tesla has been working on its unique Los Angeles diner, drive-in, and Supercharger location. Still, the company was seen performing some testing at the nearly-completed charging station earlier this month, and will reportedly be holding a job fair.

Elon Musk also responded on Monday morning to a post on X, suggesting that Tesla is “thinking about” building a U.S.-based solar Gigafactory in order to help support increased power needs with AI growth, and to bolster domestic solar production.

Tesla is building a new UFO-inspired Supercharger in the heart of Alien country

News

Tesla driver walks away from major accident with minor injuries

The driver sustained only minor injuries, and the exact cause of the crash remains under investigation.

The driver of a Tesla Model Y survived and walked away from a harrowing accident on Monday in California, only sustaining minor injuries despite the vehicle being impaled by a guardrail.

On Monday morning around 4:34 a.m., the Los Banos division of the California Highway Patrol (CHP) responded to the accident on I-5 near Panoche Road, involving a 23-year-old in a Tesla Model Y. According to a post on social media, the driver veered off the road for unknown reasons in the northbound lane, before crashing directly into the guardrail and impaling the vehicle.

You can read the full message and photos from Los Banos CHP below, as were shared in a Facebook post on Monday afternoon.

This morning a Tesla model y was traveling in the #1 northbound lane of I-5 north of Panoche Rd. For unknown reasons driver allowed V-1 to veer off the roadway, travel through a dirt center divide, and crashed into the fixed metal guardrail. Lucky for the driver he only sustained minor injuries and was able to walk away. Driving a vehicle requires 100% attention to the road. Avoid distractions and focus on driving.

Credit: CHP Los Banos (via Facebook)

Credit: CHP Los Banos (via Facebook)

Credit: CHP Los Banos (via Facebook)

In a statement to SFGate, CHP officer Myles Anderson said that the driver only sustained minor injuries, while no arrests are made and drugs and alcohol are not suspected to have been involved. The report also notes that Tesla’s “cruise control and lane assistance features” were activated, according to Anderson. However, it’s not entirely clear if this is referring to Supervised Full Self-Driving (FSD), or to the cruise control and lane assist features baked into Autopilot.

At the time of writing, CHP has not yet responded to Teslarati’s request for clarification and additional details on the matter.

Tesla Crash Safety Ratings across its lineup: pic.twitter.com/ny30R7ceji

— TESLARATI (@Teslarati) July 1, 2025

READ MORE ON TESLA SAFETY: Tesla rolls out crucial new safety feature aimed at saving children

The news comes after Tesla has touted its vehicles as incredibly safe for many years. In December, for example, the company highlighted receiving top safety scores from regulators on four different continents throughout the world, including from the National Highway Traffic Safety Administration (NHTSA) and the Insurance Institute of Highway Safety (IIHS) in the U.S.

Tesla has also listed the goal of making its vehicles the safest on the road throughout the years, both in the overall design of its vehicles and in its Autopilot and Full Self-Driving (FSD) programs.

Tesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

Investor's Corner

Cantor Fitzgerald maintains Tesla (TSLA) ‘Overweight’ rating amid Q2 2025 deliveries

Cantor Fitzgerald is holding firm on its bullish stance for the electric vehicle maker.

Cantor Fitzgerald is holding firm on its bullish stance for Tesla (NASDAQ: TSLA), reiterating its “Overweight” rating and $355 price target amidst the company’s release of its Q2 2025 vehicle delivery and production report.

Tesla delivered 384,122 vehicles in Q2 2025, falling below last year’s Q2 figure of 443,956 units. Despite softer demand in some countries in Europe and ongoing controversies surrounding CEO Elon Musk, the firm maintained its view that Tesla is a long-term growth story in the EV sector.

Tesla’s Q2 results

Among the 384,122 vehicles that Tesla delivered in the second quarter, 373,728 were Model 3 and Model Y. The remaining 10,394 units were attributed to the Model S, Model X, and Cybertruck. Production was largely flat year-over-year at 410,244 units.

In the energy division, Tesla deployed 9.6 GWh of energy storage in Q2, which was above last year’s 9.4 GWh. Overall, Tesla continues to hold a strong position with $95.7 billion in trailing twelve-month revenue and a 17.7% gross margin, as noted in a report from Investing.com.

Tesla’s stock is still volatile

Tesla’s market cap fell to $941 billion on Monday amid volatility that was likely caused in no small part by CEO Elon Musk’s political posts on X over the weekend. Musk has announced that he is forming the America Party to serve as a third option for voters in the United States, a decision that has earned the ire of U.S. President Donald Trump.

Despite Musk’s controversial nature, some analysts remain bullish on TSLA stock. Apart from Cantor Fitzgerald, Canaccord Genuity also reiterated its “Buy” rating on Tesla shares, with the firm highlighting the company’s positive Q2 vehicle deliveries, which exceeded its expectations by 24,000 units. Cannacord also noted that Tesla remains strong in several markets despite its year-over-year decline in deliveries.

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News2 weeks ago

News2 weeks agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

News2 weeks ago

News2 weeks agoWatch the first true Tesla Robotaxi intervention by safety monitor

-

Elon Musk1 week ago

Elon Musk1 week agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

News2 weeks ago

News2 weeks agoTesla Robotaxi rollout proves that Elon Musk still delivers, even if it’s late

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk commends Tesla team on successful Robotaxi launch

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk confirms Tesla Optimus V3 already uses Grok voice AI

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI welcomes Memphis pollution results, environmental groups push back