News

Tesla’s damage monitoring patent hints at cars driving to repair centers autonomously

Despite being cutting-edge machines that could be described as “the most fun thing” that anyone can possibly buy, Tesla’s electric cars are still subjected to a great deal of stress during operation. Electric cars have fewer moving parts than their fossil fuel-powered counterparts, but nevertheless, the components that move, such as their electric motors and suspension, are still subject to different types of stress.

One of Tesla’s recently published patent applications, titled “System and Method for Monitoring Stress Cycles,” discusses this particular issue. As noted by the electric car maker, machines may heat up or cool down, or speed up and slow down at different times during operation, resulting in thermal and mechanical stress. Over time, such stress could result in decreased performance, which is referred to as damage.

Damages are costly and hazardous. Stress-related damage results in equipment downtime, performance degradation, safety hazards, and maintenance expenses, to name a few. In the case of Tesla’s electric cars, these damages can cause breakdowns, or worse, accidents. To prevent this, strategies are usually employed to detect and address stress-related damage, such as repairing damaged parts or replacing components at set intervals. Tesla notes in its patent application that both practices are time-consuming and costly.

“Even regular inspections may not provide adequate protection against stress-related damage. For example, the inspections may not provide sufficient insight into the characteristics of the stresses imposed on a given component to accurately assess its condition. Moreover, the inspections themselves may be burdensome and costly,” the company wrote.

With this in mind, there is a need for a system that can detect and address stress-related damage in a more efficient and cost-effective manner.

Tesla’s recently published patent application outlines a system involving a processor configured to monitor stress imposed on subsystems while determining the cumulative damage to a vehicle’s systems. Tesla notes that a stress monitoring system would work optimally if the processor is configured to monitor stress cycles in real-time, allowing the system to avoid using too much memory in the process. Tesla describes the concept in the following discussion.

“To address these challenges, processor 140 may be configured to monitor stress cycles in real-time. For example, processor 140 may identify and record stress cycles concurrently while receiving the series of stress values from stress sensors 131-139. In some embodiments, for each received stress value in the series of stress values, processor 140 may perform one or more operations to determine whether a stress cycle has been completed. When processor 140 detects the end of a stress cycle, processor 140 may record the stress cycle immediately, such that the cumulative damage model can be continuously updated to reflect the latest recorded stress cycle.

“In some examples, real-time monitoring of stress cycles may be performed without storing the series of stress values in memory 150. For example, rather than storing a complete series of stress values for later data processing, a comparatively small number of stress values may be stored temporarily to track in-progress stress cycles, but other stress values may be discarded as soon as they are received. Accordingly, the amount of memory used during real-time monitoring of stress cycles may be reduced in comparison to alternative approaches.”

Adopting such a system gives notable benefits to electric car owners. By using a real-time monitoring model, for one, drivers would be notified by their vehicles once a component needs maintenance. In some instances, the car could immediately send stress and damage data to the company. Taking the concept even further, Tesla notes that a vehicle equipped with autonomous driving features would be able to drive itself to a service center when it needs repairs.

“In some embodiments, an operator of vehicle 110 may be notified when damage to subsystems 121-129 is detected. For example, the operator may be alerted when the level of damage reaches a predetermined threshold, such that the operator may take an appropriate remedial action (e.g., bringing vehicle 110 in for maintenance). In one illustrative example, when the level of damage is represented as a damage fraction, the operator may be alerted when the fractional damage to a given subsystem reaches 70%. In some examples, the alert may be communicated to the operator via a dashboard 160 (and/or another suitable control/monitoring interface) of vehicle 110.

“In some examples, processor 140 may be coupled to one or more external entities over a network 170. Accordingly, processor 140 may be configured to send stress cycle and/or damage data over network 170 to various recipients. For example, processor 140 may send stress cycle and/or damage data to a service center, such that service center may contact the operator to schedule a maintenance appointment when a damaged subsystem is identified. Additionally or alternately, when vehicle 1 10 is an autonomous vehicle, vehicle 110 may be instructed to drive autonomously to service center for repairs.”

Tesla is arguably one of the most proactive companies in the auto industry. For example, automotive teardown expert Sandy Munro has already dubbed the company’s batteries as the best in the market today, but Tesla’s Automotive President Jerome Guillen has stated that the company is still constantly making its batteries even better. In an interview with CNBC, Guillen pointed out that the design of Tesla’s battery cells is “not frozen.” With this in mind, it is not very surprising to see Tesla exploring proactive new ways to figure out more effective ways to monitor damages on its electric vehicles.

Tesla’s constant initiative to improve is teased somewhat in the patent applications from the company that has been published over the past few months. Among these include an automatic tire inflation system that teases off-road capabilities for the company’s vehicles, a system that addresses panel gaps during vehicle assembly, a way to create colored solar roof tiles, and even a system that uses electric cars as a way to improve vehicle positioning.

The full text of Tesla’s recently published patent application could be accessed here.

Elon Musk

Tesla to fix an FSD driver monitoring annoyance, Elon Musk hints

Elon Musk seems welcome to a change in Tesla’s Driver Monitoring suite.

CEO Elon Musk hinted in an X post that Tesla is about to fix a Full Self-Driving driver monitoring annoyance.

When using Tesla’s Full Self-Driving suite, the newest “Supervised” version allows drivers to use the vehicle without actually holding onto the steering wheel. However, a cabin-facing camera monitors the driver’s eyes, ensuring they are paying attention to the road and not abusing the suite’s capabilities.

If the vehicle recognizes multiple instances of drivers taking their eyes off the road, Full Self-Driving will be unavailable for the rest of the drive. Ending up in FSD fail is never a fun time.

However, there are some instances when the suite is perhaps a tad too critical of a driver and their eyes if they are not always looking at the road. For example, in a Tesla, adjusting things like the cabin temperature, the position of side mirrors, or even the speed offset requires the driver to take their eyes off the road for a short period of time — usually less than ten seconds.

If operating on FSD, the vehicle will alert you to look back at the road, even if you’re traveling at a low rate of speed and you only take a few seconds to adjust a setting.

During my weekend Demo Drive of the new Model Y, I experienced this:

🚨Here’s a good example of this:

I was adjusting the Autopilot speed offset and then checked back to the screen to see if anything changed.

As you can see, my eyes weren’t off the road very long before the vehicle said I needed to look out of the windshield again. https://t.co/0YKAJgXFB6 pic.twitter.com/YfiuChbDAr

— TESLARATI (@Teslarati) May 6, 2025

It appears a change could be welcome by Musk, who agreed that the warning seems excessive. How it will be changed remains to be seen, but it seems safer to be adjusting settings while FSD is active as opposed to trying to do it while driving manually:

You’re right

— gorklon rust (@elonmusk) May 6, 2025

It is good that FSD operates cautiously, as plenty of people have abused its capabilities in the past. When accidents happen due to driver irresponsibility, Tesla is not liable, but media headlines paint the picture that driving the vehicles is dangerous. In reality, Teslas travel more miles without an accident than the national average.

Tesla Vehicle Safety Report shows Autopilot is 10x better than humans

The change would likely be welcomed by many drivers, who have also complained about driver monitoring giving warnings when doing something like taking a bite of food.

News

Tesla is using this technique to expand Supercharging outside the U.S.

Tesla’s pre-fabricated Superchargers are making expansion easier for the company all over the world

Tesla is using a technique that it first used in 2021 to expand its Supercharging presence outside the United States.

In April 2021, Tesla installed its first pre-fabricated Supercharging stalls in Utah, helping streamline installation and make EV charging more widely available as the COVID-19 pandemic continued to surge on.

Tesla still utilizes pre-fabricated Superchargers, which are built at its Buffalo Gigafactory, and they are a huge asset to the company, considering they streamline the entire installation process. The chargers can be installed on a concrete slab within a matter of hours, bringing a station with numerous plugs online in the matter of a day’s work.

Tesla Semi helps install prefab Superchargers at Laguna Seca

However, Tesla is not confining this strategy to its U.S. locations only. It recently opened its first Supercharger in Estonia, where Tesla has planned to open a station for over 12 years.

It is finally set to launch its first Supercharger in Estonia this week, and North American Charging Head Max de Zegher stated that the company is utilizing the pre-fabrication technique to streamline the installation:

Long time coming! And with our pre-assembled Superchargers, which often have become our highest quality builds.

— Max (@MdeZegher) May 6, 2025

de Zegher also said the pre-fab Superchargers are Tesla’s “highest quality builds.”

Tesla has said in the past that these pre-fabricated stalls are not only more efficient in terms of the overall installation process, but they are also more cost-effective and can help save the company money on what is not necessarily a cheap part of the business.

These cost savings are then passed on to the drivers, de Zegher said in a breakdown of the pre-fab process last year. This is just one way the EV maker continues to streamline its manufacturing processes, and it does not only have to do with the vehicles, but also the equipment that charges them.

As Teslas and other EVs are becoming more popular and the charging infrastructure is still trying to catch up, pre-fab Superchargers are a great technique and strategy the company can use to expand availability. Within a matter of days, Tesla can add stalls to a station, making it easily accessible to consumers with less risk of a wait.

News

Tesla Sweden gets sweet revenge against unions with Model Y domination

It pays to have the best all-around battery electric vehicle in the market.

It is no secret that Tesla is competing in Sweden with one hand tied behind its back. With the IF Metall union and its allies pulling every trick in the book to tank Tesla’s operations in the country, one could almost expect the EV maker to push as hard as it can just to stay afloat.

Based on the Model Y’s registrations in Sweden, however, it seems like Tesla is not just staying afloat—it is actually dominating.

Tesla Model Y in Sweden

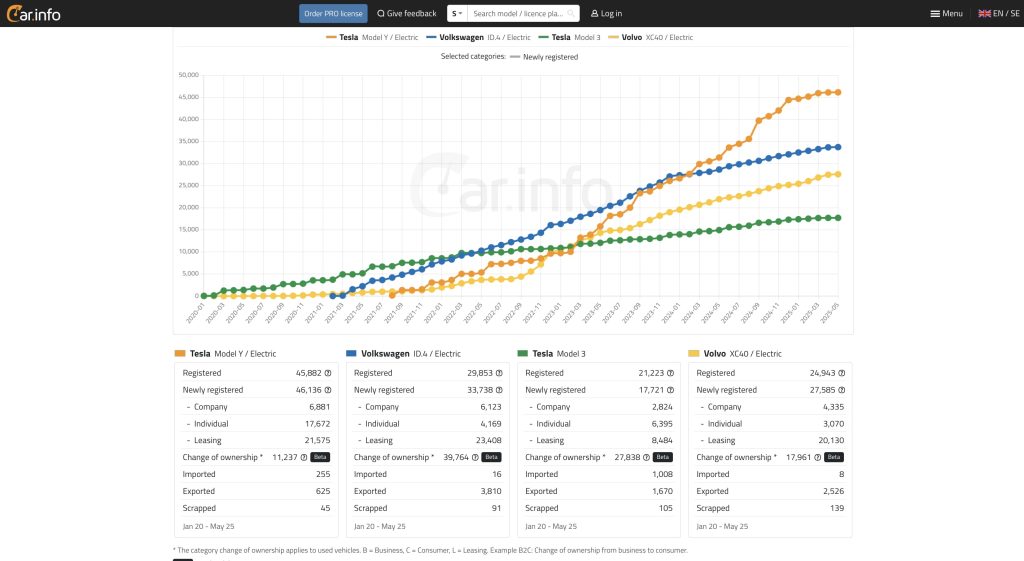

A recent compilation from Borskollen.se, citing data from car.info, has indicated that Tesla has seen a total of 45,882 Model Y registrations to date. This was enough to make the Model Y Sweden’s most popular electric vehicle. Due to its popularity, pre-owned legacy Model Y units are also seeing a drop in price, making the vehicle more attainable for Swedish car buyers.

The momentum of the new Model Y seems to be notable. Based on car.info data, Tesla saw a total of 45,200 registrations for the legacy Model Y. As of writing, at least, car.info has tracked a total of 682 new Model Y units that have been registered in Sweden so far.

What’s quite interesting is that the Model Y remained Sweden’s top electric vehicle despite a slowdown in sales during the first quarter due to the changeover to the new Model Y. For context, Sweden’s second and third most popular EVs, the Volkswagen ID.4 and the Volvo XC40, currently boast a total of 29,853 and 24,943 registrations, respectively, as per car.info data. The Tesla Model 3, the Model Y’s sibling, has seen a total of 21,223 registrations to date.

Tesla Sweden vs. the Unions

Tesla Sweden’s accomplishments and the Model Y’s sales in the country are especially impressive since the electric vehicle maker is currently facing a number of blockades and sympathy strikes from a number of Sweden’s unions. Today, unions in the country are actively attempting to disrupt, if not stop, Tesla’s operations, with some unions even flat-out refusing to activate the company’s Superchargers, which serve all electric car owners in the country.

Sweden’s unions currently seem to be learning, however, that Tesla is a very tough nut to crack. Last month alone, Tesla went ahead and launched several new Superchargers in the country. Frustrated union representatives noted that Tesla seemed to be getting around their measures by flying in people to help with its Supercharger buildout.

Back in February, Jonas Björkman, head of business development at Riddermark Bil, one of the largest used car sellers in Sweden, also stated that Tesla is the electric vehicle brand that still sees the most sales, with the Model Y and Model 3 seeing a lot of demand from consumers. “Tesla is the electric car brand we have sold the most units of, and sales continue at a high rate,” Bil stated.

-

News3 days ago

News3 days agoTesla offers legacy Model Y owners an interesting promotion

-

News2 weeks ago

News2 weeks agoTesla is trying to make a statement with its Q2 delivery numbers

-

Investor's Corner2 weeks ago

Investor's Corner2 weeks agoLIVE BLOG: Tesla (TSLA) Q1 2025 Company Update and earnings call

-

News1 week ago

News1 week agoNY Democrats are taking aim at Tesla direct sales licenses in New York

-

News1 week ago

News1 week agoWaymo considers selling robotaxis to individual owners

-

Investor's Corner2 weeks ago

Investor's Corner2 weeks agoTesla (TSLA) releases first quarter 2025 earnings results

-

Investor's Corner2 weeks ago

Investor's Corner2 weeks agoTesla (TSLA) Q1 2025 earnings: What to expect

-

SpaceX2 weeks ago

SpaceX2 weeks agoUkraine seeks Starlink alternatives from the EU